Bold Ideas Better Outcomes

cientific discoveries made by biomedical and bioengineering researchers at UNH over the past five years are transforming how a range of complex health conditions — from cancer and chronic wounds to neurological disorders such as Alzheimer’s and Parkinson’s — are being diagnosed, treated and prevented.

These discoveries, fueled by two major grant-funded initiatives at UNH, are helping accelerate the development of new vaccines, therapies, medical devices and products that are improving human health and well-being worldwide.

UNH’s Center of Integrated Biomedical and Bioengineering Research (CIBBR), funded by a $10 million National Institutes of Health (NIH) grant, is bridging the gap between basic biomedical and bioengineering research and clinical and commercial outcomes. And the New Hampshire Center for Multiscale Modeling and Manufacturing of Biomaterials (NH BioMade), a $20 million project funded by the National Science Foundation (NSF), is advancing New Hampshire’s rapidly growing biomaterials industry through knowledge generation, academic-industrial research partnerships and workforce development.

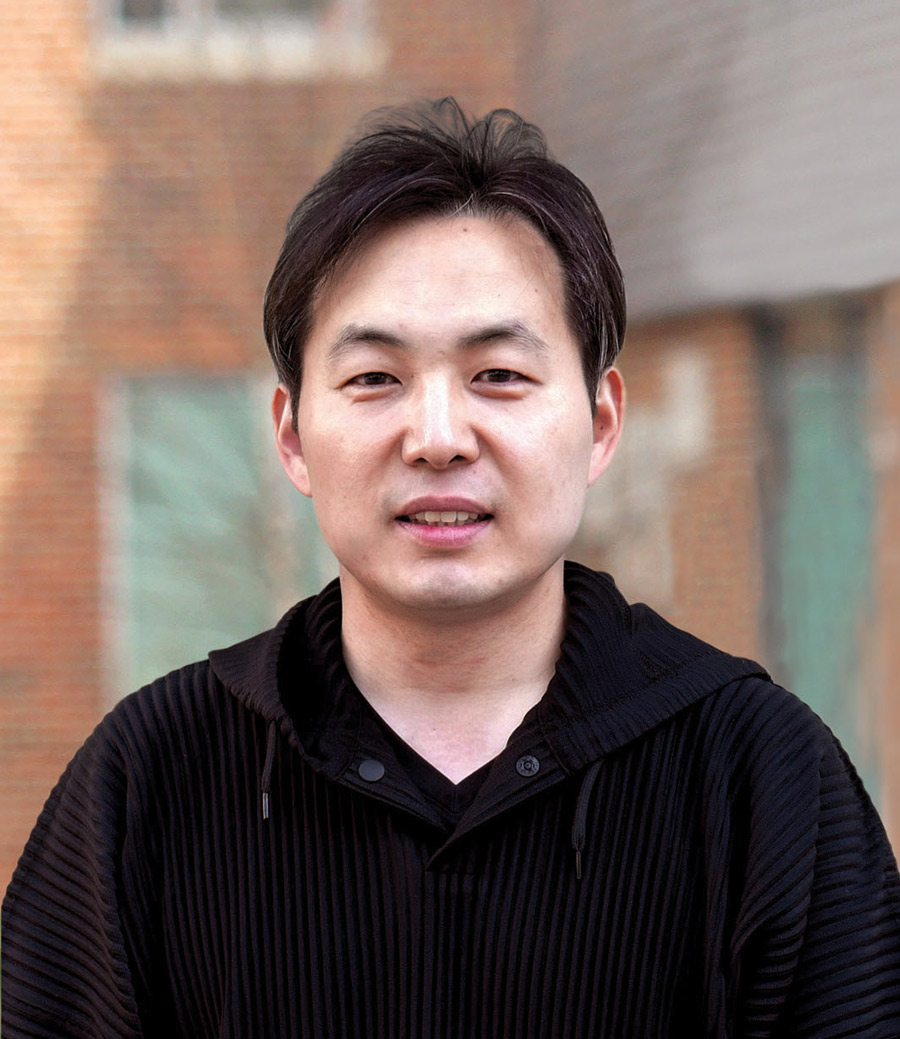

Recipients of a three-year, $600,000 NIH “Trailblazer” award in 2021, Jeong and Kim are investigating the use of melanin, a pigment made by specialized cells in the body, to deactivate matrix metalloproteinases (MMPs), an enzyme also found in human tissue that hinders the wound healing process.

“At this point, we have demonstrated the efficacy of this process in vitro, using isolated tissue in the lab,” says Jeong. “We are now at the stage of moving on to an animal study, which we hope to begin in the fall of 2023.”

The goal for Jeong and Kim is to create an injectable formulation incorporating the MMP deactivating capability they have developed and a biocompatible hydrogel that together can be applied directly to chronic wounds, creating a bandage, of sorts, that conforms to the size and shape of damaged tissue.

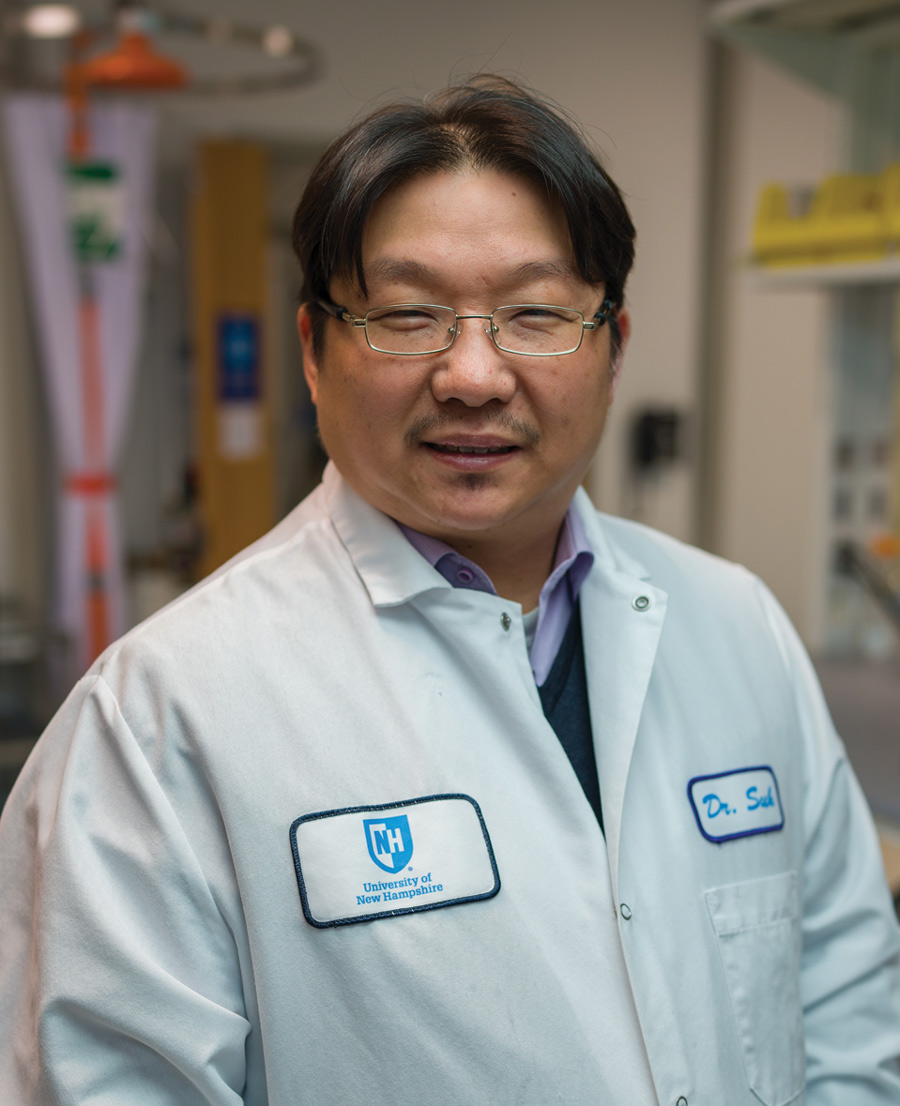

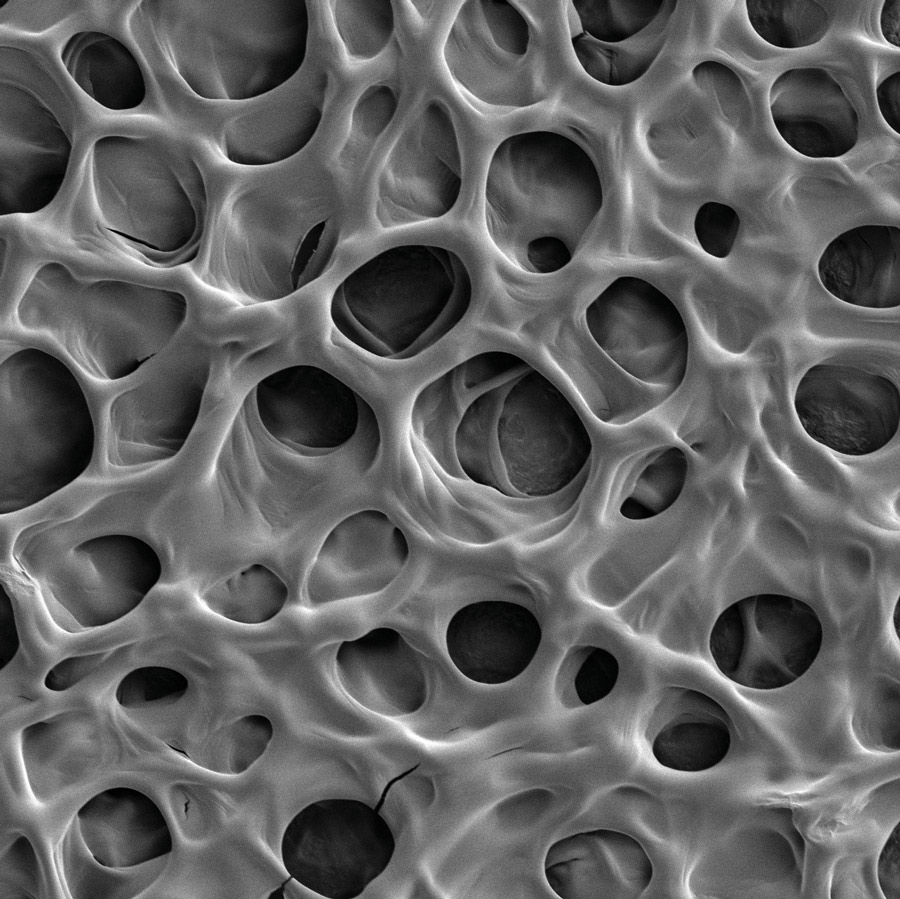

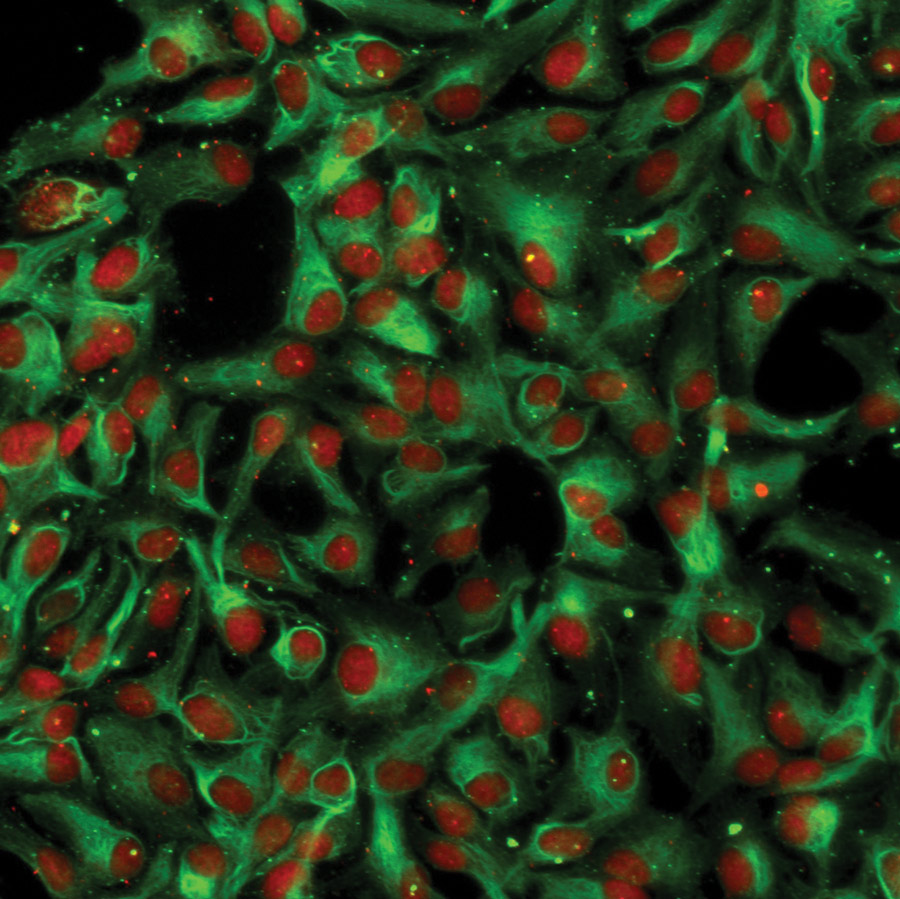

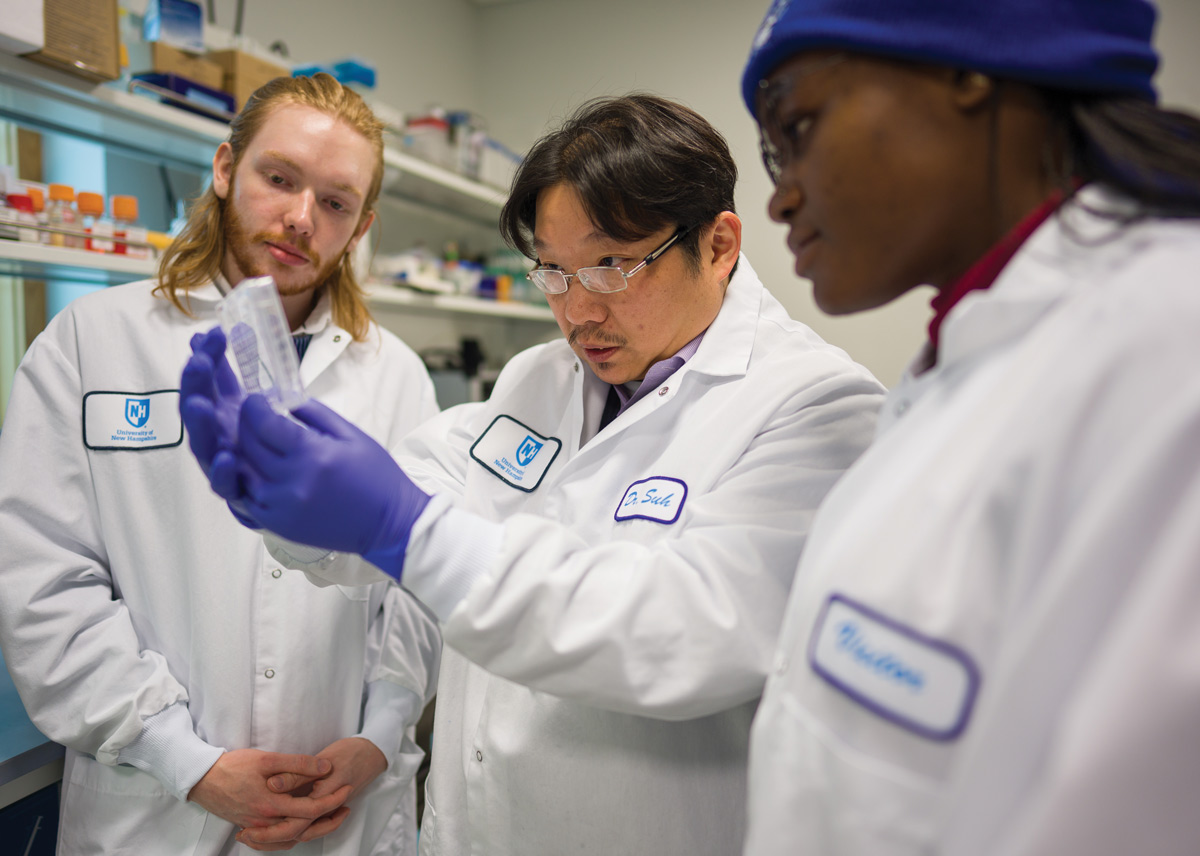

At UNH Manchester, Won Hyuk Suh, assistant professor of biotechnology, is conducting similarly innovative research focused on developing 3D bioprinting platform technologies involving in vitro models that could one day aid in the development of new treatments for patients suffering from neurodegenerative diseases and brain injuries. Suh’s work is being funded through seed grants from NH BioMade and the NH IDeA Network of Biomedical Research Excellence (NH INBRE). This research, in part, also serves as a hands-on learning model linked to broader biotech and biomanufacturing workforce development initiatives underway at UNH Manchester.

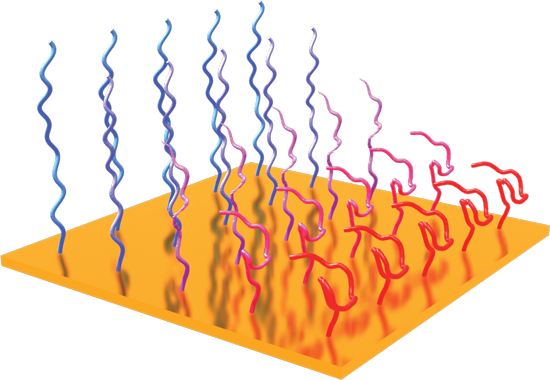

Important research being done by Harish Vashisth, professor of chemical engineering, could also enhance the treatment of neurological disorders, as well as diabetes, cancer and cardiovascular disease.

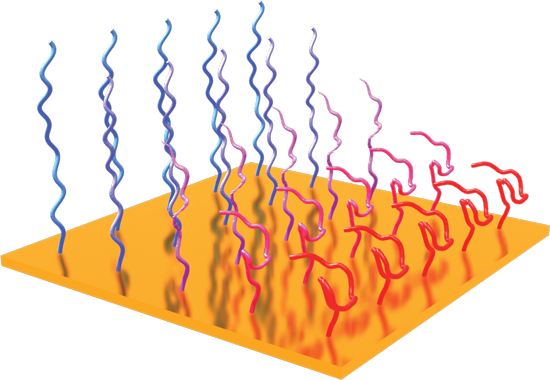

With funding from CIBBR, NH BioMade and other NIH and NSF grants, Vashisth is studying protein interactions that may improve the effectiveness of allosteric drugs, which are used to target and disrupt proteins that carry messages, or signals, that drive cellular activity and can be the cause of disease. Allosteric drugs also increase a protein’s drug affinity, which allows other drugs to be effective at lower dosages.

As an example of how these new sensors might positively impact biomanufacturing focused on human health concerns, Halpern cites how an added level of quality control in the pharmaceutical production process could reduce errors and lower costs, ultimately saving money for end users.

“Not long ago, large batches of the COVID-19 vaccine had to be scrapped because they were contaminated during the production process,” says Halpern. “This is a real issue in the manufacturing of pharmaceuticals and can cause delays that potentially impact public health and drive up costs.”

While Halpern is the principal investigator in this research endeavor, the sensor project extends far beyond UNH, with collaborators located at five academic institutions in four different states. With the grant funding from BIO-SENS, these researchers can now meet in-person once a year, hire additional graduate students to work in the lab and increase their overall output. A significant amount of the grant money, Halpern adds, will also be used to fund a range of workforce development initiatives, including an annual academic-industry biotechnology symposium (UNH will host this event in 2025), a summer workshop series and mentorship programs designed to promote diversity, equity and inclusion in the bioindustry.

Building on the success of Tech Camp and the Tech for Teachers Institute, two long-standing summer STEM programs at UNH, NH CREATES is intended to cultivate interest and expertise in core subject areas related to regenerative medicine and biofabrication among middle and high school students and teachers with the goal to address current and future workforce needs in New Hampshire’s burgeoning biotech industries. All NH CREATES programs are offered at no cost to participants and open to all levels of experience.

Members of this ecosystem are working together to develop and strengthen connections within the fields of regenerative medicine and biofabrication and facilitate entry for students interested in forging a career in these emerging industries, she adds.

NH CREATES will be expanding to the UNH Manchester campus in the near future thanks to a $1.5 million grant, part of a much larger award to a coalition led by the City of Manchester last year by the U.S. Economic Development Administration as part of the national Build Back Better Regional Challenge. The larger grant will create a biofabrication cluster in the Manchester Millyards, already home to ARMI and a growing number of biotech startups; UNH’s portion of the funds will be directed to extending the workforce development opportunities provided by NH CREATES to Manchester.